Frozen vegetable Processing Plant & Machinery

Frozen Food Processing Plant In India

In India, frozen food processing plants are becoming increasingly vital for the food industry frozen food processing plant. Not only do they offer efficient solutions for preserving food Manufacturer Frozen Food Processer, but they also support the growth of the sector Manufacturer Frozen Food Processer Popular Food Product Manufacturers. These plants are designed to maintain high standards of quality and hygiene Food Plant Suppliers in India. The technology used is both advanced and reliable, ensuring optimal preservation Popular Food Product Manufacturers. Not only is the equipment durable, but it also provides excellent performance. Processing plants cater to a wide range of frozen foods, including vegetables and fruits.

Manufacturer Frozen Food Processer

The frozen food market in India is expanding rapidly. Demand is driven by both domestic needs and export opportunities. With the rise in consumer preferences for convenience, these plants play a crucial role. They ensure that food products retain their freshness and nutritional value frozen food processing plant. Not only does this benefit consumers, but it also helps in maintaining supply chain efficiency Food Plant Suppliers in India.

Popular Food Product Manufacturers

Investing in modern processing plants offers multiple advantages Food Plant Suppliers in India. Not only does it enhance product quality, but it also increases production capacity. Efficient processing methods reduce waste and improve overall sustainability. The use of advanced technology ensures that products meet international standards frozen food processing plant. Additionally, these plants are designed to handle large volumes of food, ensuring smooth operations.

Processing Plant & Machinery

This machines remove pesticide residue, fruits and vegetables, It Removes impurities such as dust and dirt, and Give fruits an attractive marketable appearance.

MOC : SS 304

The vegetable cutting machine is suitable for cutting leaf and stem as well as root vegetables such as green scallion, celery, chili, cabbage, carrot, potato, onion, cucumber, ginger, etc.

MOC : SS 304

Blanching machines use hot water or steam to briefly cook food, preparing it for the next processing step. The process inactivates enzymes and reduces bacteria, lessening the processing load. Blanching machines can be used for a variety of food products, including vegetables, fruits, seafood, pasta, frozen foods, and meat.

MOC : SS 304

Cooling tanks in the food industry use a cooling medium to transfer heat from food products. The specific method depends on the equipment and the production process.

MOC : SS 304

Perforated basket centrifuges is in solid-liquid separation processes.

MOC : SS 304

Vibratory shaker machines, also called conveyors or shakers, are used in the food industry for a variety of tasks, including conveying, sieving, deaeration, and removing products from molds. They can also help with portioning, compacting, and separating items by size.

MOC : SS 304

The vacuum bag that contains the product is positioned in the vacuum chamber and the open side of the bag lies across the silicon rubber strip. Once the lid is being closed, the vacuum packaging machine automatically carries out the vacuum processes.

MOC : SS 304

Seperating the Material

MOC : SS 304

Transfer the Raw material in another place

MOC : SS 304

Deep freezers are used in the food industry to quickly freeze food at temperatures between -30°C to -50°C until the core of the product reaches -18°C. This process is used to preserve the nutritional characteristics of fresh foods, especially fish and vegetables, for long periods of time.

Cold storage is used to store fruits, vegetables, processed meat, Dairy Products, Spices, Dry fruits, jaggery, pulses, frozen foods, chemicals, and pharmaceutical products. · Prolonging and preserving the shelf life of food without compromising on the nutritive value.

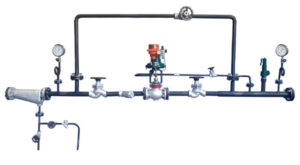

Utilities

Steam boilers are a vital part of the food processing industry, used in many of its most important processes. Steam boilers generate steam by burning fuel in a furnace, which is then piped to the food processing facility for thermal /sterilized process of the food

MOC : MS

It part of the boiler in which the high pressure steam is reduced to required steam pressure of the equipment.

MOC : MS

Steam piping with insulation to transfer the heat to the required product.

MOC : MS

Water Piping to transfer the water to the required equipment

MOC : SS 304

Electrical cables are the backbone of modern power distribution systems, and they transmit electricity from generation sources to end-users.

Water chillers are vital in food manufacturing, used for tasks like controlling fermentation temperatures in wineries and cooling mixers in bakeries. They work by circulating a refrigerant that removes heat from a process or space.

Cooling towers are used in the food industry to remove heat from water through evaporation or sterilization, which cools the remaining water. They can be customized to meet the needs of food industries, such as oil refineries, sugar, distilleries, wine, cheese, and juice. Cooling towers are also used in pasteurization and sterilization processes.

Electrical control panels are systems of electrical devices that control and monitor the mechanical functions of industrial machinery, including those used in food production. In the food industry, Electrical Control Panels are used for machinery control and conveying control.

MOC : MS

Air Compressor an accessory used in the food industries to circulate air in the system under pressure for the equipments required for piston filling , sterilizing , pneumatic operation.

MOC : MS