Ginger, Turmeric, Root Vegetable Processing Plant & Machinery

Ginger Powder Processing Machine

A Ginger Powder Processing Machine offers efficient solutions for ginger root into fine powder. It not only ensures high productivity but also maintains the quality of the final product. The machine processes fresh ginger with minimal wastage and maximum output. It not only grinds ginger to a fine consistency but also preserves its natural flavor Ginger Powder processing Machine ginger processing machinery, ginger processing machinery, ginger processing machinery, ginger processing machinery.

The machine’s design is not only compact but also highly efficient for large-scale production. It features advanced technology that not only speeds up processing but also reduces energy consumption Root Vegetable Powder Processing Machine, Root Vegetable Powder Processing Machine, Root Vegetable Powder Processing Machine, Root Vegetable Powder Processing Machine. machine is built with stainless steel, making it not only durable but also easy to clean. It is equipped with safety features that not only protect the operator but also the equipment Automatic Ginger Processing Plant, Automatic Ginger Processing Plant, Automatic Ginger Processing Plant, Automatic Ginger Processing Plant.

Maintenance of this machine is not only straightforward but also cost-effective. The parts are designed not only for long-term use but also for easy replacement when needed. Operating the machine requires not only minimal training but also basic technical knowledge. It provides a user-friendly interface that not only simplifies control but also monitors performance ginger powder production line, ginger powder production line, ginger powder production line, ginger powder production line.

This is suitable not only for small businesses but also for large factories. It not only meets industry standards but also ensures compliance with food safety regulations. The machine’s versatility allows it to not only process ginger but also other spices.

Investing in this machine means not only enhancing productivity but also ensuring consistent quality. It is not only an essential tool for the spice industry but also a reliable partner in production.

Processing Plant & Machinery

The rhizomes are used fresh or boiled in water and dried, after which they are ground into a deep orange-yellow powder commonly used as a coloring and flavoring agent in many Asian cuisines, especially for curries, as well as for the dyeing characteristics imparted by the principal turmeric constituent, curcumin.

MOC : MS

In the food industry, the bucket elevator is used for grain transport and, in general, for the height transfer of bulk products to be stored or used in production. The product is loaded into the buckets that move upwards and is released by gravity or centrifugal force.

MOC : SS 304

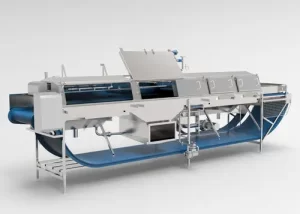

The drum washing machine is used to wash potatoes and other root products. The machine consists of a rod drum and frame. By choosing a certain distance between the rods, the maximum size of the impurities to be separated & thus the product get cleaned.

MOC : SS 304

It is usually done when the solid is dissolved in the liquid. Vacuum Filtration – In this method of filtration, a funnel and a hose are used which help to suck the fluid through the filter by creating a vacuum. This speeds up the separation and the solid gets dried.

MOC : SS 304

Centrifugal pumps are widely used in the food and beverage industry to move low-viscosity fluids. They work by converting rotational energy into hydrodynamic energy using a rotating impeller.

MOC : SS 304

Fruit washing machines remove pesticide residue, fruits and vegetables, It Removes impurities such as dust and dirt, and Give fruits an attractive marketable appearance.

MOC : SS 304

The machine is equipped with rotating soft/hard brushes which properly clean , removes hair and peels the vegetables under water spray. Vegetable washing and peeling machines are used in the food industry to clean, peel, and polish fruits and vegetables. They can be used as standalone machines or as part of a processing line. The machines are designed for a variety of vegetables and fruits, including root crops, leafy greens, and more

MOC : SS 304

The heating can be done by hot water, steam or other liquids in a continuous or batch manner. A blancher immerses the product in the hot water or steam and maintains it at a constant temperature.

MOC : SS 304

This method circulates the chilled water more efficiently resulting in faster cooling times, especially of more viscous or the frozen products.

MOC : SS 304

This machine is used for transfering, and inspecting the fruits/vegetables through eye sight. It removes the skull portion of the Fruit/vegetables. It consists of Belt and structure.

MOC : SS 304

The raw material enters into the machine feeding part, they will move forward by vibration force generated by the vibration eccentric device. During the moving process with the vibration, most water droplets of the surface can be removed.

MOC : SS 304

Metal detectors in the food industry use a transmitter-receiver method to detect metal contamination in food products. They work by creating an electromagnetic field that’s disrupted by the presence of metal.When a metal particle passes the detector it interferes with the electromagnetic field, causing a signal to be detected by the receiver coils.

MOC : SS 304

The food material is fed into the machine, and as the screw turns, it pushes the material through the compression zone, gradually increasing the pressure. As the material moves through the compression zone, the water is forced through the perforated screen, leaving behind the dewatered solid material.

MOC : SS 304

The vegetable cutting machine is suitable for cutting leaf and stem as well as root vegetables such as green scallion, celery, chili, cabbage, carrot, potato, onion, cucumber, ginger, etc.

MOC : SS 304

Principle of Tray dryer: In tray dryer, hot air is generated by the electric heaters or steam in radiator coils is continuously circulated through the perforated trays with material to be dried. Forced convection heating takes place to remove moisture from the solids placed on trays.Working on effective drying process.

MOC : Contact Part-SS 304 & Non-Contact Part MS

The conveyor will cool the product with the use of air circulation, while it is being transported from the hot air oven to the next process.

MOC : SS 304

Powder Making Section

Screw conveyors, also known as auger conveyors, are commonly used in the food industry to transport, lift, and mix food materials. They use a rotating helical screw blade, called a flighting, to move materials through an enclosed tube or trough.

MOC : MS

Pulverizers are used to pulverize pieces of raw materials into fine particles. Pulverizers have three functions, pulverization, drying and classification.

MOC : Contact Part-SS 304 & Non-Contact Part MS

A Vibro sifter is a machine that uses vibration to sift or separate various materials with the help of different sieves.

MOC : SS 304

Form fill seal packaging machines use a reel of flexible material and either form it into a tube and then seal and fill it at regular intervals, or fold it lengthwise and seal it at right angles to the fold to form a series of pockets which are filled and closed.

MOC : SS 304

Utilities Section

Steam boilers are a vital part of the food processing industry, used in many of its most important processes. Steam boilers generate steam by burning fuel in a furnace, which is then piped to the food processing facility for thermal /sterilized process of the food

MOC : MS

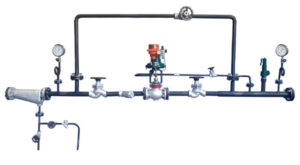

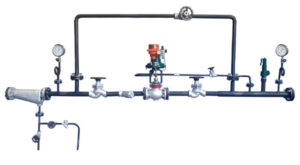

It part of the boiler in which the high pressure steam is reduced to required steam pressure of the equipment.

MOC : MS

Steam piping with insulation to transfer the heat to the required product.

MOC : MS

Water Piping to transfer the water to the required equipment

MOC : SS 304

Air Piping to transfer the air to the required equipment

MOC : SS 304

Air Compressor an accessory used in the food industries to circulate air in the system under pressure for the equipments required for piston filling , sterilizing , pneumatic operation.

MOC : MS

Electrical control panels are systems of electrical devices that control and monitor the mechanical functions of industrial machinery, including those used in food production. In the food industry, Electrical Control Panels are used for machinery control and conveying control.

MOC : MS

Electrical cables are the backbone of modern power distribution systems, and they transmit electricity from generation sources to end-users.

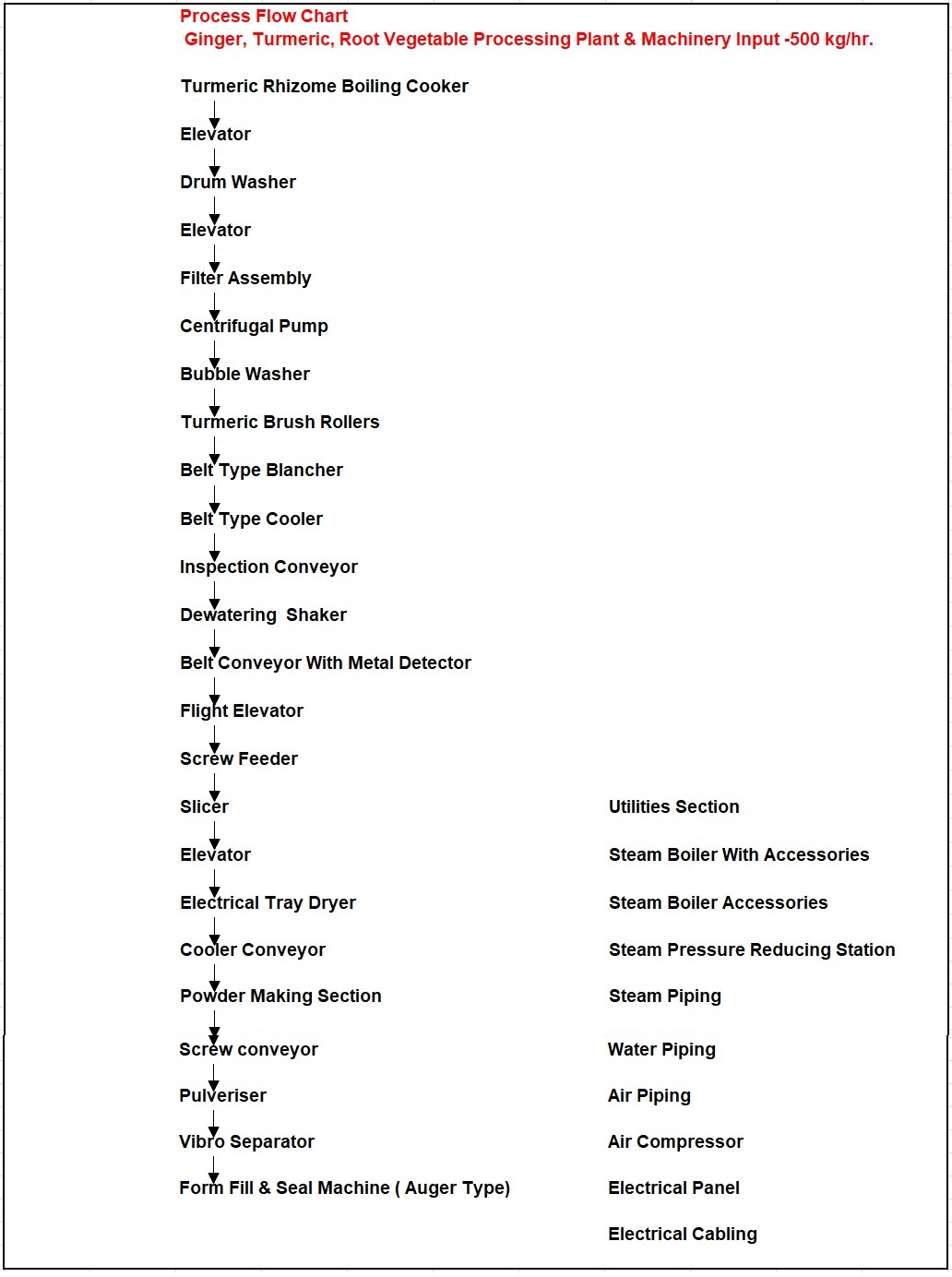

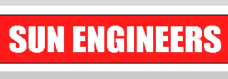

Process Flow Chart