Sweet Corn & Green Peas Processing Plant & Machinery

Sweet Corn Processing Plant

The essential for transforming fresh corn into products enjoyed worldwide Sweet Corn Food Processing Plant. These plants not only increase efficiency but also enhance product quality significantly Sweet Corn Processing Unit. Advanced machinery ensures a seamless transition from raw corn to finished products. The technology used in these plants helps preserve the freshness and nutritional value of the corn Sweet Corn Production Plant, Sweet Corn Manufacturing Plant,

Efficient processing reduces waste and maximizes yield, making the plants environmentally friendly. Each plant is designed with both functionality and durability in mind. Not only does this lead to better productivity Sweet Corn Production Plant, but it also supports sustainability efforts Sweet Corn Food Processing Plant. The process involves cleaning, husking, and milling Sweet Corn Manufacturing Plant, which are all vital steps Sweet Corn Food Processing Plant.

By utilizing modern equipment, manufacturers can deliver high-quality corn products to the market Sweet Corn Processing Unit. With increasing demand, investing in a sweet corn processing plant can be highly beneficial Sweet Corn Processing Unit.

The integration of automation streamlines operations and reduces manual labor. Also, training staff is crucial for maintaining high standards in processing Sweet Corn Production Plant Sweet Corn Manufacturing Plant.

Quality control is emphasized throughout the processing stages. Additionally, maintaining rigorous hygiene standards prevents contamination and ensures product safety. Investments in innovation and technology drive the industry forward.

Sweet Corn Processing Plant & Machinery

The pods are fed into the machine, where blades beat the pods to remove the peas. The peas fall through a perforated sheet onto an inclined conveyor belt, while the pods and peels stick to the belt and are collected in separate chutes.

MOC : SS 304

This machine is used for transfering, and inspecting the fruits/vegetables through eye sight. It removes the skull portion of the Fruit/vegetables. It consists of Belt and structure.

MOC : SS 304

Conveyor belts are crucial in the food industry, moving ingredients and finished products through various processing stages. They can help reduce labor-intensive tasks and minimize contamination risk.

MOC : SS 304

In the food industry, the bucket elevator is used for transfer and, in general, for the height transfer of bulk products to be stored or used in production. The product is loaded into the buckets that move upwards and is released by gravity or centrifugal force.

MOC : SS 304

In the food industry, in used blowing air through the mixture or dropping the mixture through a tube with a constant upward airflow which allows the nibs to drop while the thin shells blow up and away.

MOC : SS 304

The process of water tunnel and pass through a preheating area, where it is gradually heated to the desired pasteurization temperature by hot water spraying onto the surface of the containers.

MOC : SS 304

Fruit washing machines remove pesticide residue, fruits and vegetables, It Removes impurities such as dust and dirt, and Give fruits an attractive marketable appearance.

MOC : SS 304

In the food industry, the bucket elevator is used for transfer and, in general, for the height transfer of bulk products to be stored or used in production. The product is loaded into the buckets that move upwards and is released by gravity or centrifugal force.

MOC : SS 304

The heating can be done by hot water, steam or other liquids in a continuous or batch manner. A blancher immerses the product in the hot water or steam and maintains it at a constant temperature.

MOC : SS 304

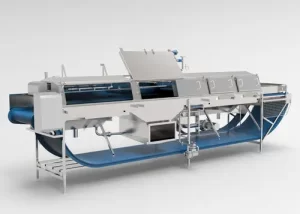

The cooling tunnel is characterized by a two-zone design with countercurrent cooling. In the first zone, the warm product moves along with the belt and is placed under the cold air stream. The heated air is transferred to a separate second zone, where it is cooled down again.

MOC : SS 304

This method circulates the chilled water more efficiently resulting in faster cooling times, especially of more viscous or the frozen products.

MOC : SS 304

Green Peas Processing Plant & Machinery

The raw material enters into the machine feeding part, they will move forward by vibration force generated by the vibration eccentric device. During the moving process with the vibration, most water droplets of the surface can be removed.

MOC : SS 304

This machine is used for transfering, and inspecting the fruits/vegetables through eye sight. It removes the skull portion of the Fruit/vegetables. It consists of Belt and structure.

MOC : SS 304

The Z-type bucket elevator is in a closed shell, and is driven by a chain. The material strip is fixed with the hopper, and the hopper is loaded with materials. In this way, the equipment can be made into single-point and multi-point feeding and discharging

MOC : SS 304

The raw material enters into the machine feeding part, they will move forward by vibration force generated by the vibration eccentric device. During the moving process with the vibration, most water droplets of the surface can be removed.

MOC : SS 304

IQF is used in the frozen food industry to maintain the quality, texture, and nutritional value of fruits & vegetables.

Electrical control panels are systems of electrical devices that control and monitor the mechanical functions of industrial machinery, including those used in food production. In the food industry, Electrical Control Panels are used for machinery control and conveying control.